Posted on Monday 18th November, 2024

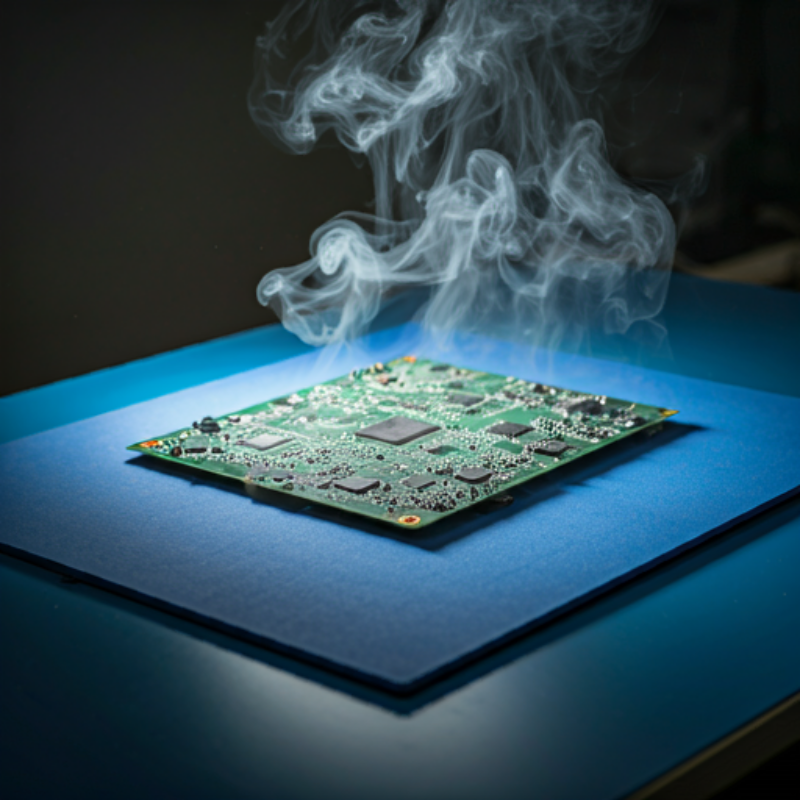

Protecting Electronics with Low-Outgassing ESD Mats

A product's outgassing performance is often just as crucial as its mechanical and electrical specifications, especially when used in sensitive device and printed circuit board manufacturing. The outgassing performance of a material is important not only in areas with electronics, but also in areas using sensors, lenses, or mirrors because oxidation can change the optical behavior.

It’s vital to understand how to reduce outgassing to protect critical components in many industries, such as aerospace, semiconductor, automotive, and medical.

While protective conformal coatings on circuit boards can help prevent sulfur from reaching the components, low-outgassing dissipative mats can further reduce sulfur exposure to electronic components especially while the PCB is unprotected in its pre-coated state.

In the case of ESD tablemats, outgassing is the process of releasing gas that was previously trapped, absorbed, or embedded in the material and will release a gas when exposed to heat or placed in a vacuum. This gas will eventually condense onto metal components placed on the mat and may compromise or degrade the metal surface.

ACL Staticide understands how crucial it is to mitigate contamination of sulfur outgassing, so we use a third party to ensure our Dualmat .08 dissipative material has low sulfur content. Using an ASTM-approved technique, samples are combusted to 1350 °C in an atmosphere of pure oxygen. The sulfur is oxidized to sulfur dioxide and quantified by infrared absorption.

By prioritizing low-outgassing materials, diverse industries can safeguard the performance and longevity of their sensitive electronics, ensuring that critical components remain protected from contamination and degradation.

This entry was posted in ESD Workbench Products. Bookmark the permalink.